Our Products

Download Now

Mail Us Now

Get immediate Response

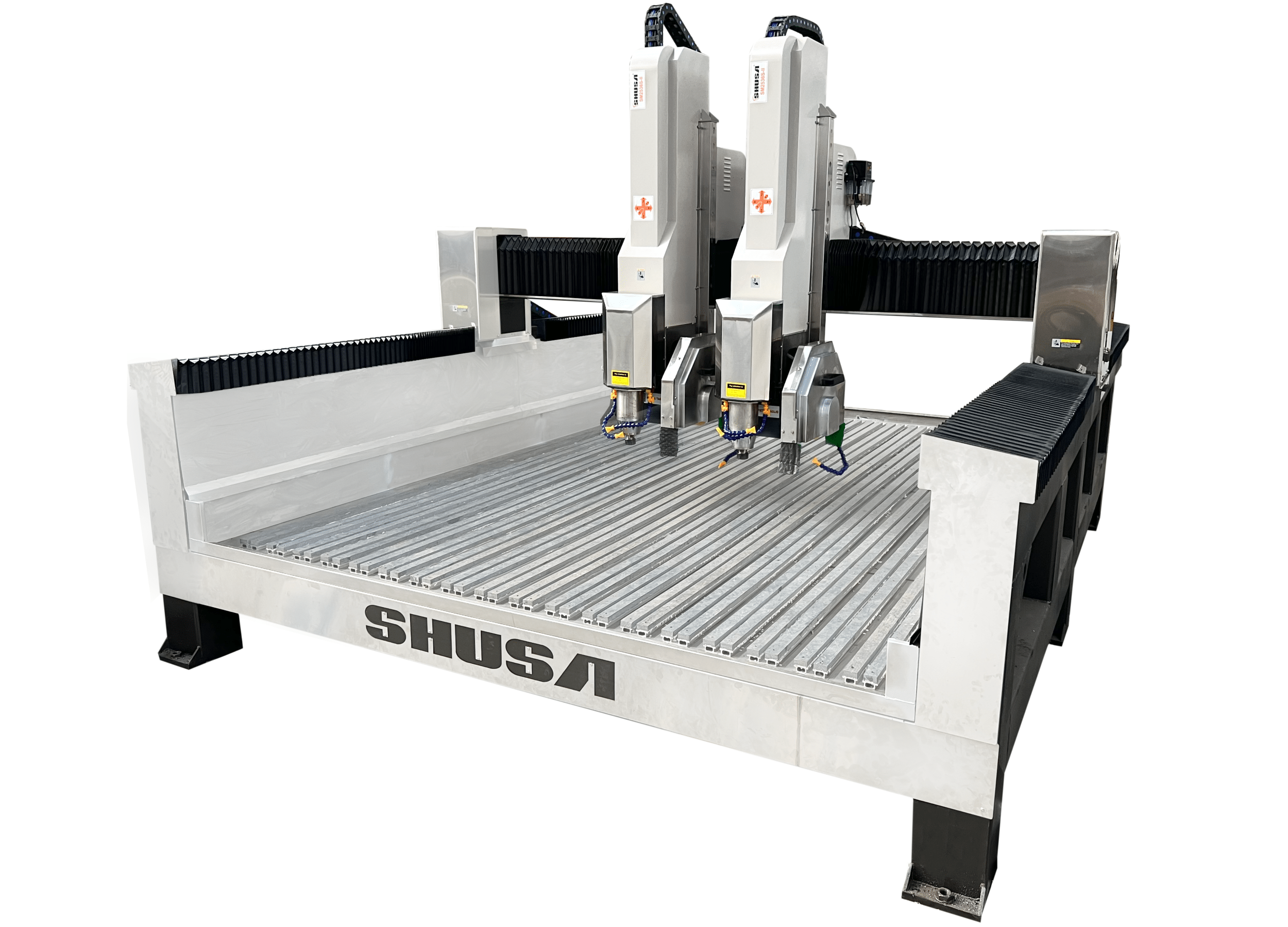

SM 2536 S2B2

CNC Stone Profiling & Carving Machine

Technical Specifications

Highly precise machining on X Y Z axis to achieve accurate positioning and long life repeatability.

Zero backless gear boxes in X Y Axis to withstand Stone cutting load and less maintenance.

Accurate Servo Motor in all Axis to get faster and trouble free operations.

Automatic Lubrication in all axis for smoother working condition and increase machine life

High speed spindle 24000 rpm for detailed carving and higher production.

Ceramic balls in bearing of Spindle for less noise also increasing spindle running hours

Z axis Servo Motor with break to get mark free operation on working surface

Guided way machining for LM Guide and Rack in All axis for best geometry and alignment.

Center Water tray for hassle free bed cleaning and safe environment

Imported Bellows Covers and Cable track guide to increase life of LM Guide and Cables respectively.

| Item | SHUSA SM 2536 S2B2 Inta-Profo |

|---|---|

| Working Table Size(mm) | 2600 x 3700 mm |

| X Axis Stroke | 2500 mm |

| Y Axis Stroke | 3600 mm |

| Z Axis Movement(mm) | 450 mm |

| Gantry Height(mm) | 800 mm |

| No Of head | 2 head |

| Head 1 | Spindle for Tool Carving & Blade for Profiling |

| Head 2 | Spindle for Tool Carving & Blade for Profiling |

| Spindle Details | 10 HP // 24000 Rpm // ER 32 |

| Blade Details | 13 HP / 3000 Rpm//450 mm Blade Dia //50 mm hole |

| Motor & Drive | 1500 W AC Servo Motor & Drive |

| Linear Guide | 30 mm Taiwan LM Rail in X Y and Z Axis |

| Max Moving Speed | Z axis : 3 mtr/min |

| Z Axis Motor | Z Axis Motor with Break 1500 W |

| Power Transmission | Ultra Precision Planetory Gear Box & Heavy duty 24x24 mm Helical Rack Pinion |

| Self Lubrication System | 3 set Automatic with Timer Adjustment |

| Control System | Control Handle Remote NK105 |

| Spindle Cooling | Water Circulation with Tank & Pump |

| Tool Cooling | Water Pump & Slurry Tank |

| Total Power(kw) | 24 KW |

| Machine Leveling | 6 Set Anti Vibration Leveling Pad |

| Axis Rail Covers | Bellows Dust & Water proof covers on X & Y Axis |

| Pen Drive | 32 GB |

| Gross Weight (kg.) | 2380 Kg |

| Packing Size | 4600 x 3600 x 2410 |

| Covers and Tray | Stainless Steel Covers and Tray |

| Working Table Size(mm) | 2600 x 3700 mm |

Applications

Freequently Asked Question

SHUSA CNC stone engraving machine is a computer-controlled machine used to carve, cut, and engrave designs into various types of stone materials. It is commonly used for creating intricate patterns, text, Inlay , Jali , murals , wall panel , textures on stone surfaces.

SHUSA CNC stone engraving machines can work with a variety of stones including granite, marble, limestone, sandstone, slate, and more. Different stones may require different settings and tools for optimal results.The same machine also capable to work on Wood,MDF,courian, ACP,Acrylic,FRP, Glass.

SHUSA CNC Stone machines are widely used in the temple construction, Building Construction,art, monument making, interior design, and manufacturing industries. They are often employed for producing tombstones, decorative tiles, countertops, sculptures, and custom stone products.

Our CNC stone engraving machine works by following a set of computer instructions (G-code) to move a rotating tool (such as a diamond-tipped bit) along specified paths, removing material to create the desired design. The machine's movements are controlled by motors and a computer system.

Operator/Programmer should draw on Computer software and generate a G code program for the same, machine will read that program and follow the desired path.

Operator/Programmer should draw on Computer software and generate a G code program for the same, machine will read that program and follow the desired path.

Important features to consider include the machine's size, spindle power, precision, speed, compatibility with different stone types, ease of use, and the availability of customer support and maintenance services.