Our Products

Download Now

Mail Us Now

Get immediate Response

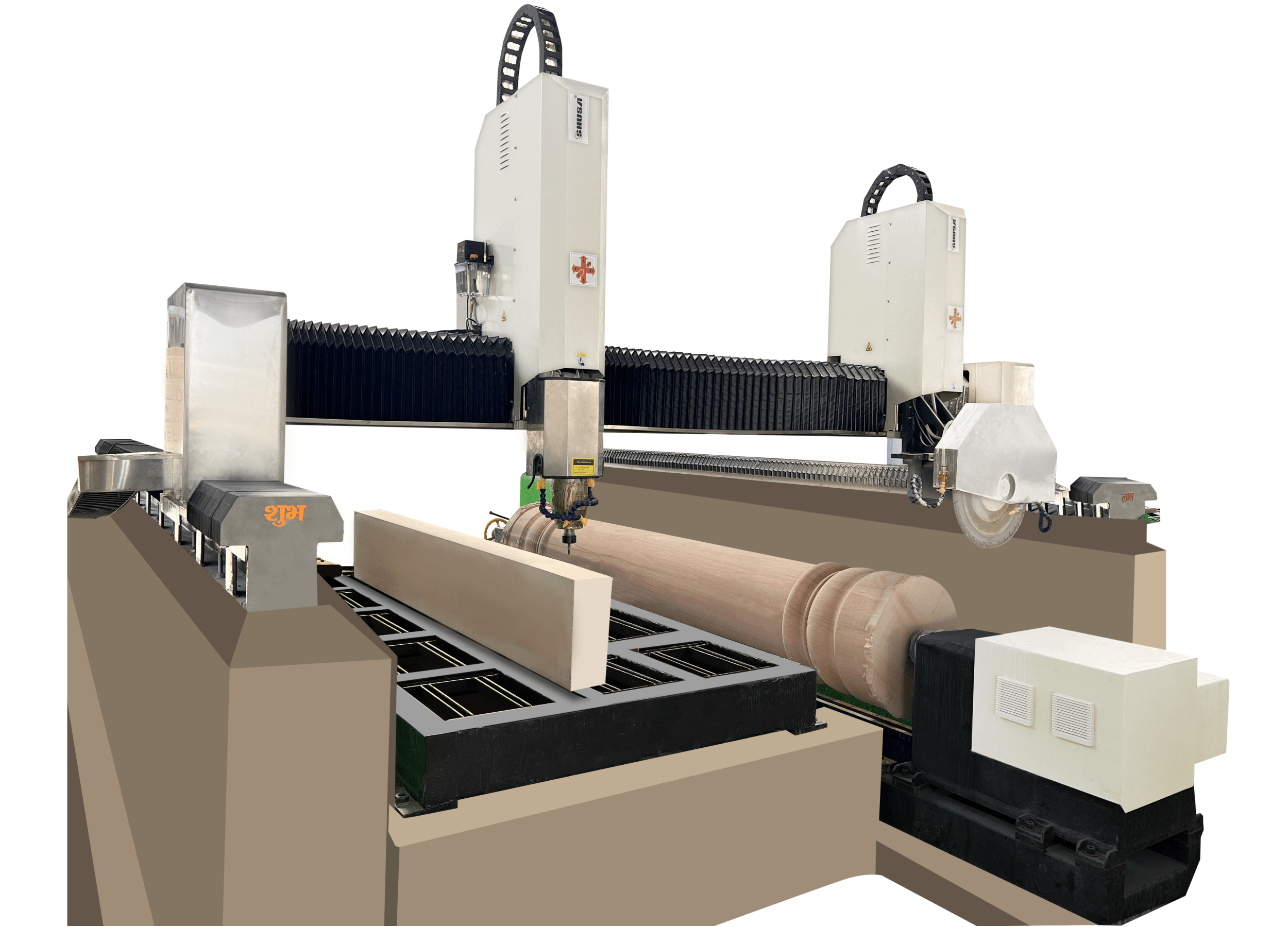

SM 3036 SB R600

CNC Stone Column Turning & Carving Machine

Technical Specifications

| Item | SHUSA SM 3036 SB R600 |

|---|---|

| CNC Lathe Stone Diameter | Max 600 mm- Min 100 mm |

| CNC Lathe Stone Length | Max 3000 mm - Min 300 mm |

| Max Engraving Size on Table | 3000 mm x 1200 mm |

| Np Of Head | 2 |

| Cutting Stroke of Blade X Axis | 2200 mm |

| Cutting Stroke of Blade Y Axis | 3600 mm |

| Max vertical Travel of Blade Z axis | 450 mm |

| Controller | 4 axis Controller with Computer & 17'' screen |

| Power Transmission | Ultra Precision Planetory Gear Box & Heavy duty 24x24 mm Helical Rack Pinion |

| Self Lubrication System | 3 set Automatic with Timer Adjustment |

| Motor Drive | 1500 W Servo motor & Drive in all Axis |

| Blade Spindle Power | 13HP |

| Max Blade RPM | 3000 Rpm |

| Tool Spindle Power(HP) | 10 HP |

| Max Tool Spindle Speed(Rpm) | 24000 rpm |

| L M Guide | 30 mm LM Guide in all Axis |

| Blade Cutter Diameter | 450 mm |

| Tool Diameter | 1-20 mm |

| Total Power(kw) | 26 KW |

| Profiling On CNC lathe | Yes |

| Profiling On Fix Table | Yes |

| Carving on CNC Lathe | Yes |

| Carving On Fix Table | Yes |

| Engraving Table Size (Optional ) | 3000 mm x 1200 mm |

| CNC Lathe Stone Diameter | Max 600 mm- Min 100 mm |

| CNC Lathe Stone Length | Max 3000 mm - Min 300 mm |

| Max Engraving Size on Table | 3000 mm x 1200 mm |

Applications

Freequently Asked Question

SHUSA CNC stone engraving machine is a computer-controlled machine used to carve, cut, and engrave designs into various types of stone materials. It is commonly used for creating intricate patterns, text, Inlay , Jali , murals , wall panel , textures on stone surfaces.

SHUSA CNC stone engraving machines can work with a variety of stones including granite, marble, limestone, sandstone, slate, and more. Different stones may require different settings and tools for optimal results.The same machine also capable to work on Wood,MDF,courian, ACP,Acrylic,FRP, Glass.

SHUSA CNC Stone machines are widely used in the temple construction, Building Construction,art, monument making, interior design, and manufacturing industries. They are often employed for producing tombstones, decorative tiles, countertops, sculptures, and custom stone products.

Most CNC stone engraving machines come in 3-axis, 4-axis, and 5-axis configurations.

A 4-axis machine adds a rotary axis or tilting Axis allowing for more intricate designs and engraving on cylindrical or curved surfaces.