Our Products

Download Now

Mail Us Now

Get immediate Response

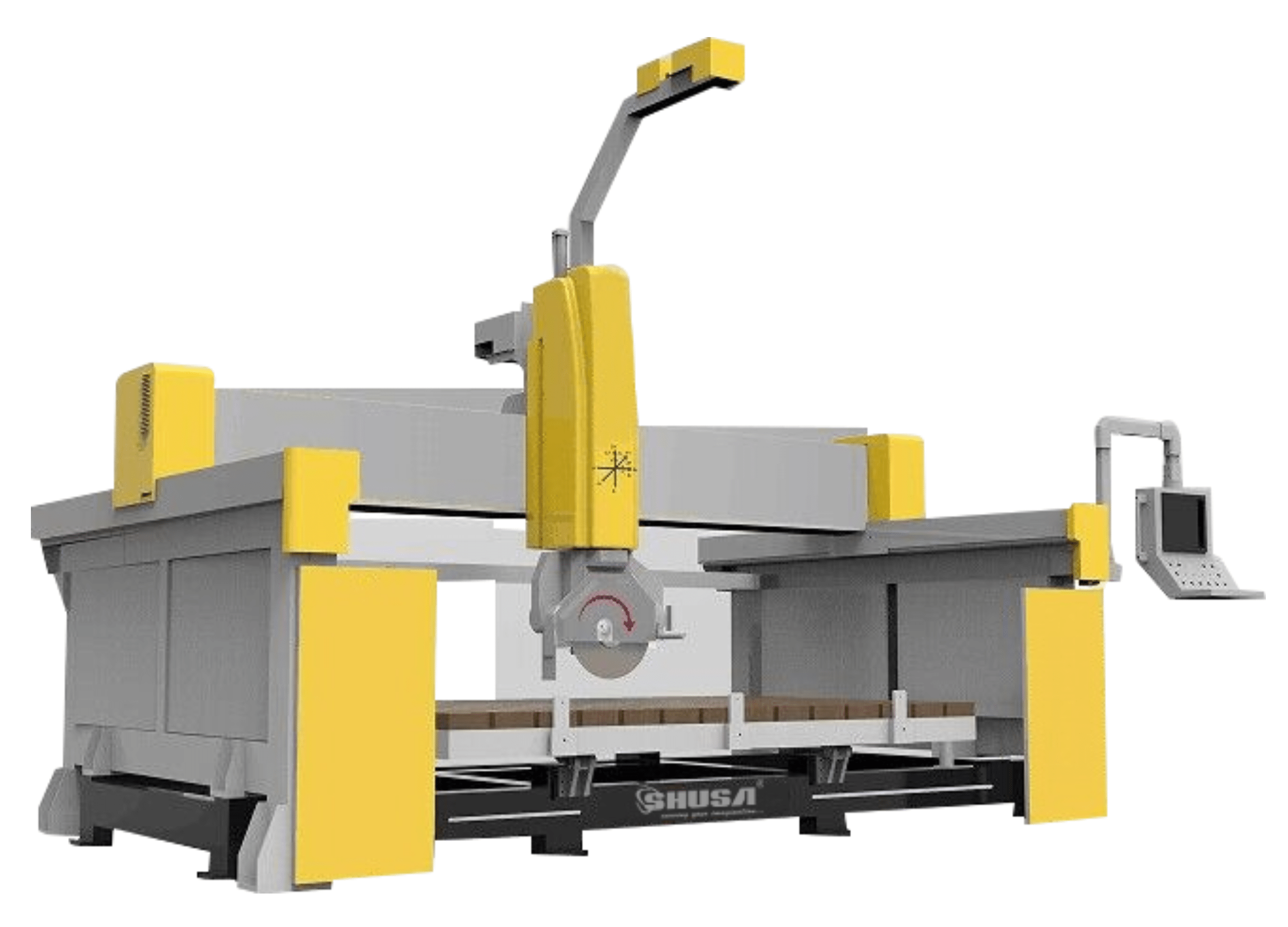

Cubo 625 - 5A

CNC Bridge Saw Machine

Technical Specifications

| Item | SHUSA Cubo 625 5A |

|---|---|

| Working Table Dimension | 3200 mm x 2000 mm |

| 126 inch x 78.5 inch | |

| Cutting Stroke of Blade-X AXIS | 3350 mm (132 inch) |

| Cutting Stroke of Blade-Y AXIS | 2290 mm (90 inch) |

| Z Axis Stroke of Blade | 400 mm |

| Max Blade Rotation- C AXIS | 0 to 360 Degree Interpolated |

| Blade Tilting Capacity - A Axis | 0 to 90 Degree Interpolated |

| Sink Hole Cutting | Yes |

| Internal Circle Radius Cuuting | Yes |

| Max Diameter Of Blade | 625 mm |

| Blade Hole Diameter | 50 mm |

| Blade Locking Flange Diameter | 200 mm |

| Max Cutting Depth | 200 mm |

| Max Machine moving Velocity | 15 mtr/min |

| Power Of Blade Motor | 22 KW |

| Max Blade Speed | 3000 Rpm |

| Variable Speed of Blade | Yes |

| Water Consumption at 2 bar | 30 litre / minute |

| Total Machine Power | 30 KW |

| Machine Outer Size | 5500 x 3300 x 3500 mm |

| CAD CAM Software | Inbuilt CAM Software with PolyGone cutting Feature |

| Tilting Table (Optional) | 0 to 85 degree with Hydraulic Pump |

| Camera (Optional) | High resolution with Online cutting feature |

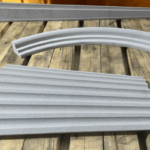

Applications

Freequently Asked Question

SHUSA CNC stone engraving machine is a computer-controlled machine used to carve, cut, and engrave designs into various types of stone materials. It is commonly used for creating intricate patterns, text, Inlay , Jali , murals , wall panel , textures on stone surfaces.

SHUSA CNC stone engraving machines can work with a variety of stones including granite, marble, limestone, sandstone, slate, and more. Different stones may require different settings and tools for optimal results.The same machine also capable to work on Wood,MDF,courian, ACP,Acrylic,FRP, Glass.

SHUSA CNC Stone machines are widely used in the temple construction, Building Construction,art, monument making, interior design, and manufacturing industries. They are often employed for producing tombstones, decorative tiles, countertops, sculptures, and custom stone products.

Most CNC stone engraving machines come in 3-axis, 4-axis, and 5-axis configurations.

A 4-axis machine adds a rotary axis or tilting Axis allowing for more intricate designs and engraving on cylindrical or curved surfaces.