CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, providing unparalleled precision and efficiency. Whether you’re a hobbyist looking to expand your workshop capabilities or a business aiming to enhance your production process, purchasing your first CNC machine is a significant step. Here’s what you need to know before making that investment.

Understanding CNC Machines

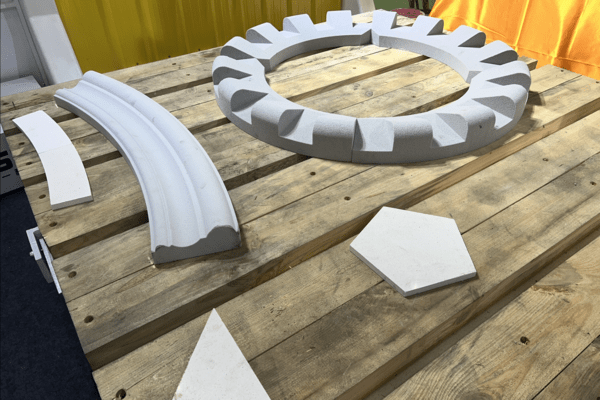

CNC machines use computer programs to control machining tools such as lathes, mills, routers, and grinders. These machines can cut, drill, and shape materials with high accuracy, making them invaluable for various applications, from prototyping to mass production.

Types of CNC Machines

Before diving into the purchase, it’s crucial to understand the different types of CNC machines available:

CNC Mills: These are versatile machines used for cutting and drilling materials. They are ideal for creating complex parts and are widely used in manufacturing.

CNC Lathes: These machines rotate the material against a cutting tool. They are perfect for producing cylindrical parts like shafts and bushings.

CNC Routers: Primarily used for cutting and shaping wood, plastic, and soft metals, CNC routers are popular in the woodworking and sign-making industries.

CNC Plasma Cutters: These use a high-velocity jet of ionized gas to cut through metal. They are essential for metal fabrication and construction.

CNC Laser Cutters: Using a laser beam to cut materials, these machines offer high precision and are used in industries like aerospace, automotive, and electronics.

Key Considerations Before Buying

1. Define Your Needs

The first step in purchasing a CNC machine is understanding what you need it for. Consider the following:

- Materials: What materials will you be working with? Different machines handle different materials better.

- Complexity: What level of detail and complexity do your projects require?

- Volume: Are you producing one-off custom parts or large production runs?

2. Budget

CNC machines range in price from a few thousand dollars to over a hundred thousand dollars. Set a realistic budget that includes not only the machine but also accessories, software, and maintenance costs.

3. Space Requirements

CNC machines can be large and heavy. Ensure you have adequate space in your workshop or factory, including room for material handling and maintenance.

4. Software

CNC machines require CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create and execute designs. Check if the machine comes with software or if you need to purchase it separately. Also, ensure the software is compatible with your computer system.

5. Support and Training

Invest in a machine from a reputable manufacturer that offers comprehensive support and training. Proper training is crucial for safe and efficient operation. Look for manufacturers that provide detailed manuals, tutorials, and customer support.

6. Maintenance

Regular maintenance is vital for the longevity and performance of your CNC machine. Understand the maintenance requirements and ensure you have the skills or resources to perform them. Some manufacturers offer maintenance packages, which can be a worthwhile investment.

7. Precision and Tolerance

Different CNC machines offer varying levels of precision and tolerance. Ensure the machine you choose can meet the specific accuracy requirements of your projects.

Making the Purchase

Once you’ve defined your needs and considered the key factors, it’s time to start looking at specific models. Visit trade shows, read reviews, and join CNC forums to gather information and user experiences. Don’t hesitate to reach out to manufacturers for demonstrations or to ask questions.

Setting Up Your CNC Machine

After purchasing your machine, follow these steps to get started:

Installation: Carefully follow the manufacturer’s installation instructions. Ensure the machine is on a stable surface and properly calibrated.

Training: Take advantage of any training offered by the manufacturer. Familiarize yourself with the machine’s controls, software, and safety procedures.

Test Runs: Begin with simple test runs to get a feel for the machine. Gradually increase the complexity of your projects as you become more comfortable.

Maintenance Schedule: Establish a regular maintenance schedule to keep your machine in optimal condition. This includes cleaning, lubrication, and part replacement as necessary.

Conclusion

Purchasing your first CNC machine is an exciting venture that can significantly enhance your capabilities. By understanding your needs, setting a realistic budget, and thoroughly researching your options, you can make an informed decision that will serve your projects well. Proper setup, training, and maintenance are crucial for maximizing the benefits of your investment. Happy machining!